Same if the towers aren't all parallel to each other, square to the print surface and equidistant (with a specific distance) to each other it'll cause errors in the prints because the kinematics wont quite match up with the real printer. On a delta if any one of the arms aren't the same in length it'll cause issues (granted, whether they matter depends on your use case) that aren't as easy or at least not as intuitive to diagnose. If the print is a few degrees off square, easy diagnosis and easy fix. If the two Y rails are a few mm further apart in reality compared to the plans? Again, no big deal. On a coreXY if one rail is slightly longer than it should be, no big deal.

More so that they are more "fussy" mechanically. I'm not saying deltas are bad, or can't achieve good results. it's much easier and more intuitive to diagnose. If something is off with the print, like squareness, dimensions, flatness etc.

For a beginner, especially if you're thinking of self sourcing/self designing, a coreXY is much simpler, more intuitive and forgiving. Large delta printer, E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerodĭisclosure: I design Duet electronics and work on RepRapFirmware.

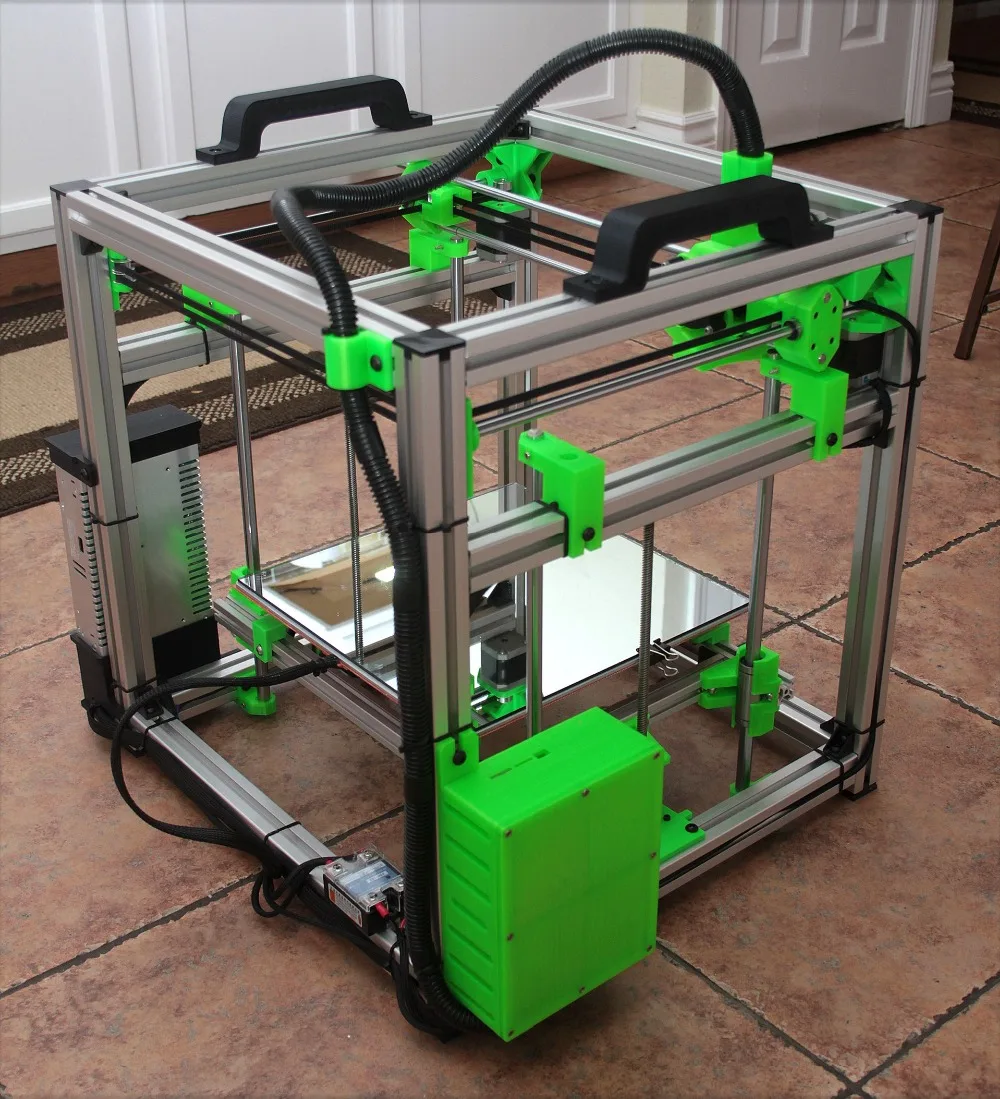

HYPERCUBE COREXY UPGRADE

The RailCore guys are working on a tool changing variant, which could be an interesting upgrade if you choose that design.Įdited 2 time(s). It's hard to do multi-extrusion or tool changing on a delta, and Bowden extruders are normally used on deltas (sometimes with a flying extruder to shorten the Bowden tube). CoreXY will cost more and take up more desk space, but is more versatile. Delta is mechanically simpler and costs less than CoreXY, but is still not cheap to get a good quality printer with decent build volume - mine cost over £1000 Both need to be built accurately and solidly to work well Here are some options:ĭelta self-build: my large Kossel design (see link in my signature) You will have plenty of opportunity to make changes to it later. If you have never built your own printer before, then I suggest you choose either a good kit or a good existing design. Your thoughts on this are welcome.Įdited 2 time(s). Now I have read of problems that some Hypercube builders have had and I'm curious to know of the percentage of successful builds there are, or are many Hypercubes a perpetual work in progress? And I'm not trying to start any format wars here but a good well tuned Hypercube made from premium parts vs a well tuned delta with premium parts such as the Seemecnc, which would produce the better prints, or would it be a wash? Is there a design advantage of one format over the other that lends itself to higher print quality? I can see that the potential for aggravation would be much greater building Hypercube vs the Seemecnc but the Hypercube could likely be built for less than the Rostock V4 and there is that accomplishment factor again.

On the other hand there is that sense of pride and accomplishment that comes from building something from plans. I'm an Rc'er that has built many fixed wing and helicopter kits and flown them successfully over the years so I'm 100% sure that the Seemecnc kit would get built and work as advertised. I like the idea that the Hypercube allows for some flexibility when building such as different extruders etc. The difference is the Seemecnc has good factory support and comes as a complete kit vs the total diy aspect of the Hypercube with no factory support, only community support. But I also think the Hypercube Evolution is a good printer. I would like to build a high quality kit and on most days I tend to go for the Seemecnc Rostock v4 kit. 300x300x300 or thereabouts is all the build area that I need. I have narrowed the field down to either a delta or a core xy machine.

I've been lurking on this and other forums for some time now trying to educate myself on the pro's and con's of all of the different platforms. I'm wanting a printer to replace my Monoprice maker v2.

0 kommentar(er)

0 kommentar(er)